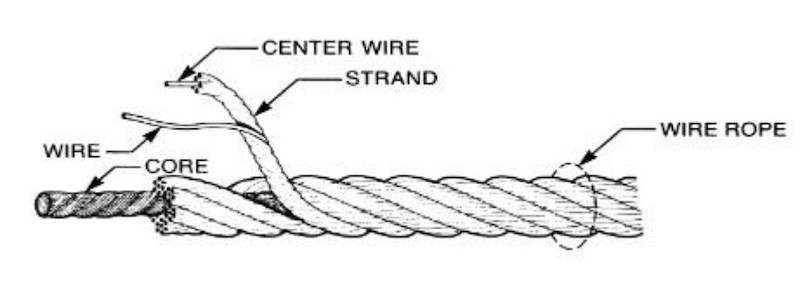

The three basic components of a typical wire rope. (Fiber core is shown.)

COMPONENTS: Wire rope consists of three basic components.

1. Wires.

2. Strands, formed by wires, laid helically around a core.

3. Core, or center.

MATERIAL: Steel grades in wide use today are IPS (improved plow steel), EIPS (extra improved plow steel), sometimes also referred to as XIPS, XIP, or EIP, as well as EEIPS (extra, extra improved plow steel).

CORE: Its function is to provide proper support for the strands under normal conditions. Three types of core (or center)

are commonly used.

1. Fiber Core (F.C.), usually polypropylene (P.C.), sometimes hemp (H.C.) and sisal.

2. Independent Wire Rope Core (IWRC)

3. Wire Strand Core (WSC)

IWRC and WSC are sometimes referred to as steel wire core or steel center.

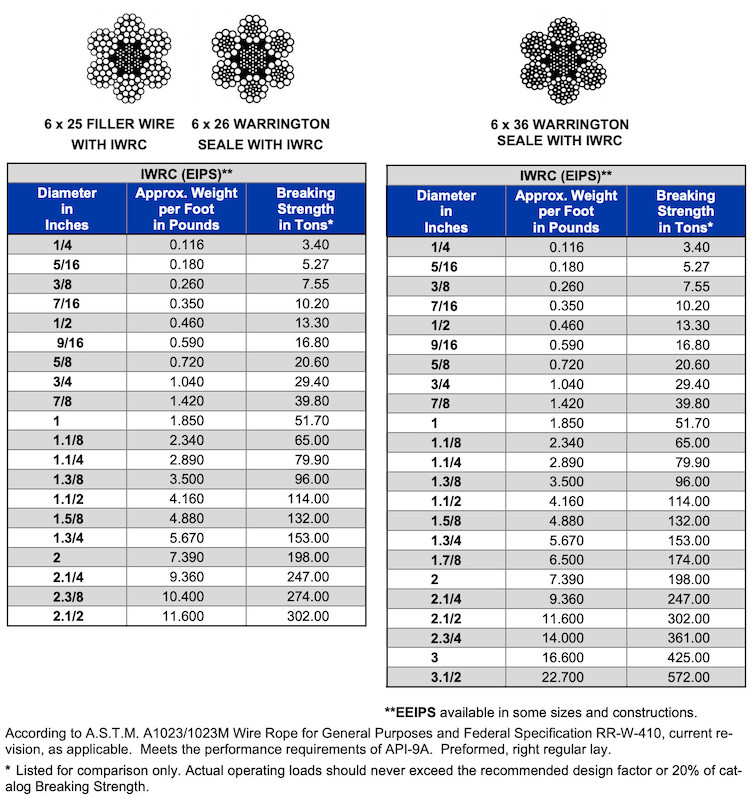

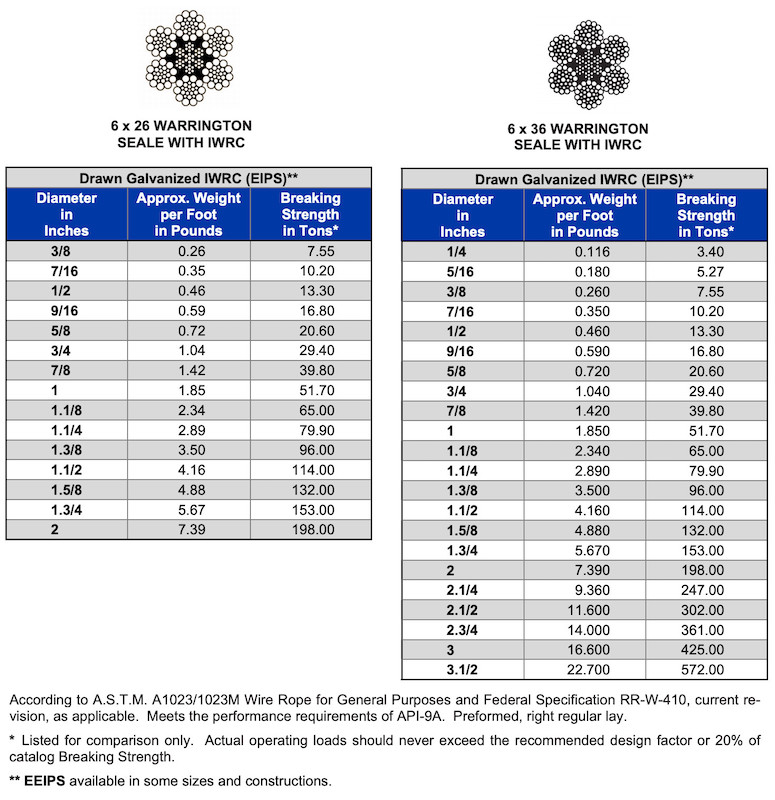

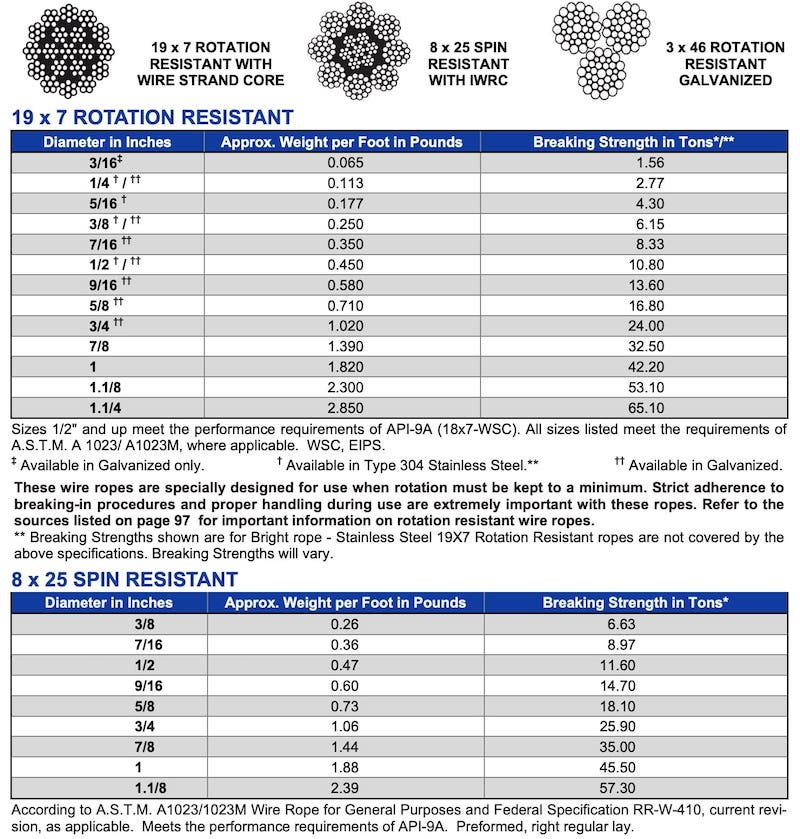

CONSTRUCTION: Expressed in numbers of strands x number of wires. 6 x 25 indicates that the wire rope consists of 6 strands, which in turn have 25 individual wires.

Constructions are grouped into classes:

6 x 7 Class: Containing 6 strands that are made up of 3 through 14 wires, of which no more than 9 are outside wires.

6 x 19 Class: Containing 6 strands that are made up of 15 through 26 wires, of which no more than 12 are outside wires.

6 x 36 Class: Containing 6 strands that are made up of 27 through 49 wires, of which no more than 18 are outside wires.

8 x 19 Class: Containing 8 strands that are made up of 15 through 26 wires, of which no more than 12 are outside wires.

19 x 7 Class: Containing 19 strands, each of which is made up of 7 wires.

8 x 19 and 19 x 7 class wire ropes have rotation-resistant properties, excluding elevator ropes.

The constructions listed above are just some of the more popular constructions.

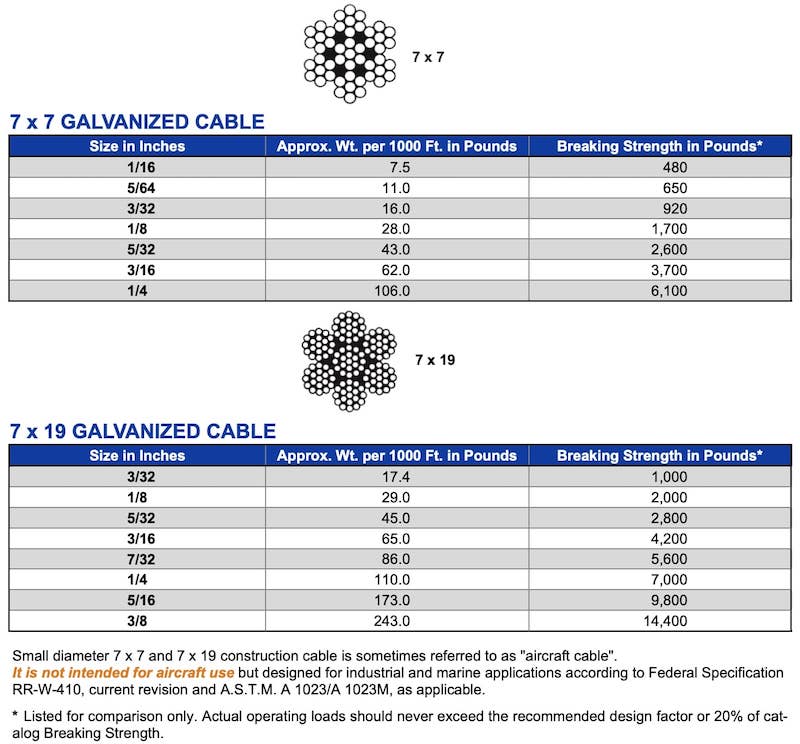

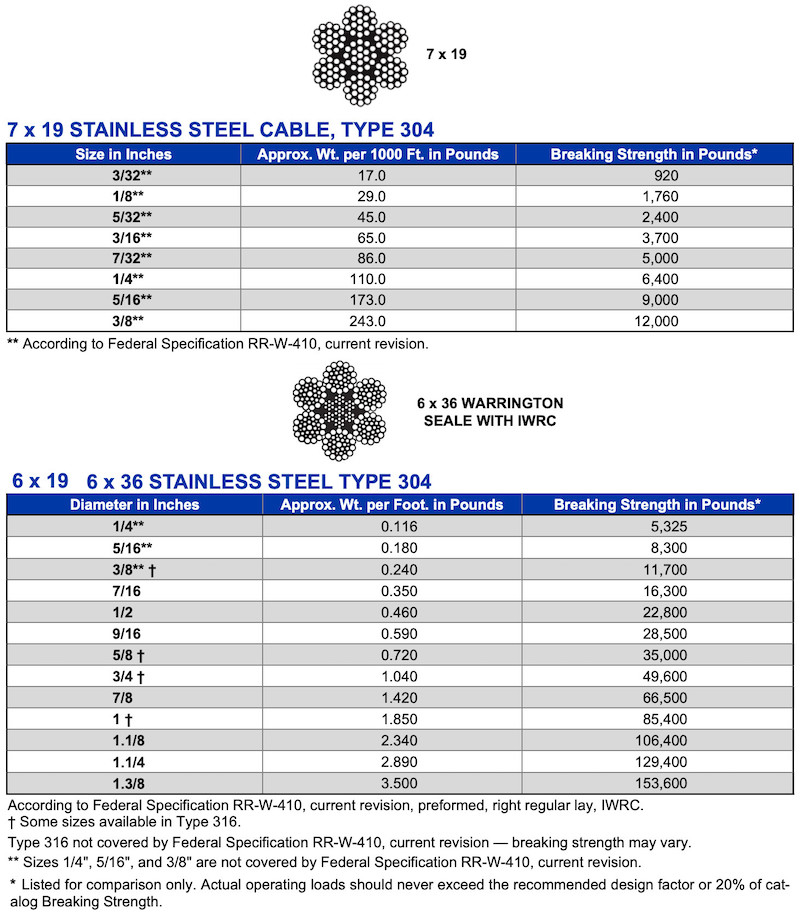

Other common constructions: 7 x 7, 7 x 19: Galvanized cable. Sometimes referred to as "aircraft cable" but not intended for aircraft use. 1 x 7, 1 x 19: Strand 7 x 7 x 7, 7 x 7 x 19: Cable Laid

Many others exist, some for highly specialized applications only.

Note that any class denotes the nominal number of wires in each strand. The actual number of wires may be different.

For example 6 x 36 class: strands most commonly consist of 36 wires, or 31, or 41.

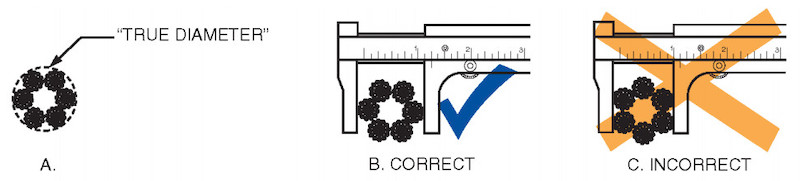

MEASURING OF WIRE ROPE

How to measure (or caliper) a wire rope correctly. Since the "true" diameter (A) lies within the circumscribed circle, always measure the larger dimension (B). Actual diameter can be 5% larger than nominal wire rope diameter.

RECEIVING AND STORING WIRE ROPE

Make certain that the wire rope received is the one that was ordered. Check for obvious damage to wire rope and reel.

Store wire rope away from heat, moisture and other corrosive agents. This means storing under a weatherproof cover,

off the ground, preferably in a dry, cool, well ventilated warehouse. If wire rope has to be kept outdoors, cover it with a

coating of protective wire rope lubricant and cover both wire rope and reel with waterproof material. Keep it well off the

ground. Careful inspection after extended storage is of utmost importance.

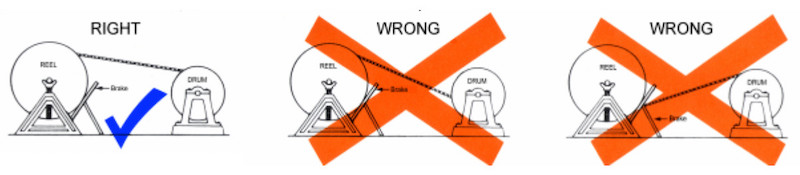

UNREELING OR UNCOILING WIRE ROPE

Great care must be taken when removing wire rope from reels or coils. Looping the rope over the flange of the reel or

pulling the rope off a coil while it is lying on the ground will create loops in the line. If these loops are pulled tight, kinks

will result, thereby permanently damaging the wire rope. Check illustrations below showing correct and incorrect ways of

unreeling and uncoiling wire rope.

Whenever handling wire rope, take care not to drop reels or coils. This can damage wire rope and collapse the reel,

making removal of the wire rope extremely difficult if not impossible.

RE-REELING WIRE ROPE

When reeling wire rope from one reel to another it is preferable for the wire rope to travel from top to top, as illustrated.

Spooling from bottom to bottom is also acceptable, provided the surface over which the wire rope will travel is clean,

smooth and dry, so as not to allow foreign particles to become embedded in the wire rope. Spooling from top to bottom

or from bottom to top can put a reverse bend into wire rope and must be avoided. When stringing up on machinery wire

rope should be removed from the reel in the same direction as placed on the drum.

CUTTING & SEIZING WIRE ROPE

There are numerous ways to cut wire rope - use only appropriate tools specifically designed to cut wire rope. Safety goggles and work gloves must always be worn. Observe other precautions peculiar to the tools used. Wire rope should be properly seized on both sides of the cut with wire or strand. Seizing wire diameter and the number and length of the seizings will depend on the diameter of the wire rope, and whether or not it is preformed.

BREAKING IN NEW WIRE ROPE

Since wire rope is a machine with many moving parts, it requires careful installation and breaking in procedures for maximum safety and long service life. After proper installation, allow the wire rope to run through a cycle of operation at a very low speed. Keep a close watch on the wire rope, its attachments and any working parts such as sheaves, drums, rollers, etc. to make certain that the wire rope runs freely. If no problems appear at this stage, run the wire rope through several cycles of operation under light load at reduced speed. This procedure allows the component parts of the new rope to make a gradual adjustment to the actual operating conditions.

WIRE ROPE EFFICIENCY

Wire rope will develop 100% efficiency, that is, break at or above minimum acceptance strength (not less than 2 1/2% below nominal breaking strength) under controlled laboratory conditions. Once fittings such as sleeves, clips, sockets, etc. are attached and/or the wire rope passes over a curved surface such as sheaves, pins, etc. its strength is decreased. In the case of wire rope passing over a curved surface this decrease in strength depends on the severity of the bend. In the case of wire rope fittings, the decrease in wire rope strength will depend on the type of fittings used. The wire rope efficiency usually ranges from 70% - 100%. For more detailed information consult the strength efficiency of wire rope table on page 86. Note, that hand spliced wire rope, while not using any fittings, has less efficiency than properly flemished and swaged wire rope. There are other factors, depending on the application of wire rope, that can cause a decrease in nominal wire rope strength. They must be considered when choosing a design factor. Refer to the Wire Rope Users Manual and/or other qualified sources for details.

ELASTIC PROPERTIES OF WIRE ROPE

Wire rope is an elastic member; it stretches or elongates under load. This elongation can be permanent or recoverable. The extent of elongation will depend on the wire rope used and the design factor chosen. While it may be acceptable for many wire rope uses to neglect its elastic properties, they are of critical importance for some uses. When in doubt about the importance of wire rope elongation consult professional help. Pre-stretching wire rope will only remove some of the constructional stretch and will not totally eliminate elongation under load.

WINDING WIRE ROPE ON DRUMS

Installation of wire rope on a plain or grooved drum requires a great deal of care. Make certain the wire rope is properly attached to the drum. Keep adequate tension on the wire rope as it is wound onto the drum. Guide each wrap as close to the preceding wrap as possible, or follow the groove in case of a grooved drum. No blanket recommendations can be given concerning direction of winding, desirable drum diameter, fleet angle, etc. Consult the Wire Rope Users Manual for this and other important technical information.

WIRE ROPE SLINGS

Refer to ASME standard B30.9 and OSHA standard 1910.184 for design factors and other important information. Other standards and information may apply.